Features

Single Stage centrifugal End suction Pump

Horizontal back pull out design for easy Maintenance

Designed accordance to DIN 24255 (10bar Pressure)

Flanges as per DIN 2533 (PN16)

Suction x Delivery- 50x32 to 200x150 mm

Maximum Head up to 150 Meter & Maximum Discharge up to 550 m^3/hr

2900 & 1450 RPM

Operating Temperature up to 120 deg

Normal Mechanical Seal (SiC Vs Sic with Viton Below) up to 90 deg & high temperature seal up to 120 deg

Grease packed Ball Bearings for no maintenance and longer Bearing life

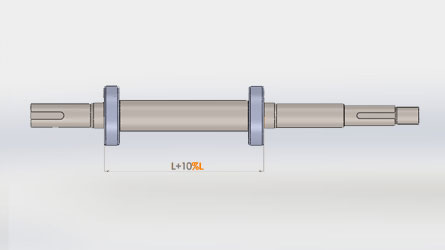

Stainless steel Sleeve to protect the Shaft

Available in various MOC (Cast Iron, Bronze & Stainless Steel)